PURCHASING MANAGEMENT SYSTEM

Supplier Approval

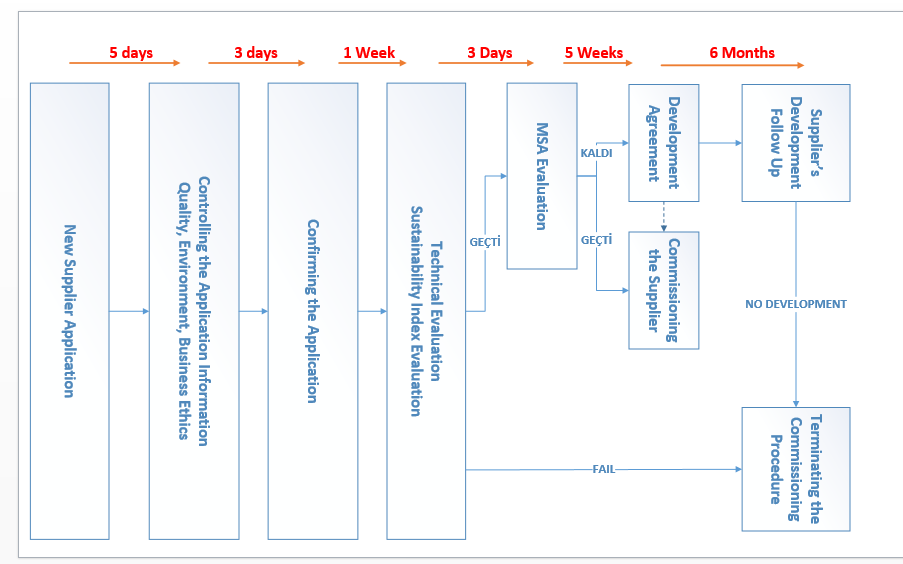

Candidates who want to be the supplier of Iran Home Appliances go through the “Supplier Approval / Evaluation” process. Within the scope of this process, suppliers are evaluated to cover many steps such as commercial, business ethics, environment and quality including Iran Home Appliances Responsible Purchasing Policy perspective. If it deems necessary, Iran Home Appliances has the right to have its supplier audited on site or to have it inspected by independent organizations. Approval workflow is given above.

Contracts

Iran Home Appliances (P.J.S.) establishes commercial relations with its suppliers, based on mutual trust, constructed with a sense of responsibility and communication, and having well-defined contents and limits set by the ability to compromise.

Iran Home Appliances (P.J.S.) mutually signs the “Purchasing Contracts” with its suppliers in order to have the working conditions bilaterally defined and provide continuity of such conditions.

The main purpose of the contracts are:

- Bilaterally defining the working conditions

- Determining the measures and procedures in case they are not met

Signing supplier contracts is the primary condition for cooperation between Iran Home Appliances and its suppliers. Suppliers are obliged to fully comply with the terms of the contract. Contracts are also the commitment of long-term cooperation between the two parties. Supplier contracts include business ethics, environmental and quality requirements, as well as commercial matters.

Non-Conformance Management

Zero-defect products, delivery on time, environment compliance and Code of Conduct compliance constitute critical expectation of Iran Home Appliances (P.J.S.) for a sustained cooperation.

If the supplier conducts non-conformity, Iran Home Appliances (P.J.S.) can demand the supplier to carry out corrective actions, to take precautionary measures against potential non-conformities and compensate the Company’s losses.

The supplier is obliged to form a system to evaluate these demands, to plan corrective and precautionary actions against non-conformance and to inform Iran Home Appliances (P.J.S.) about the results of these plans and applications.

Quality complaints and “Corrective/Precautionary Action Requests” filed to the supplier by Iran Home Appliances (P.J.S.) must be responded in writing by means of 8D forms.

The supplier’s reply should meet the following requirements:

Temporary measures taken against the problem should be reported within 48 hours. These temporary measures cover re-inspections, sorting, inventory separation and product blockages. Permanent measures taken against the problem should be reported within 10 business days.

The report of permanent measures should include:

- Description of the problem’s main cause

- Steps of corrective action

- Steps of precautionary measures if the steps of corrective action can be extended to other processes affecting Iran Home Appliances

- Definition of responsibilities and time schedule regarding corrective action.

If the supplier does not restore the non-conformities actively and these problems are continuous, it constitutes the reason for decommissioning and termination of contract is considered.

Order And Shipment

After completing sample approval process held by Product Plants and meeting the conditions of pricing and payment inspected by Purchasing Directorate, the suppliers are given mass production orders by Production Planning Directorates under Iran Home Appliances (P.J.S.) production plants. Later, orders are confirmed and the materials are sent to the relevant product plants.

To ensure a sustainable growth in today’s highly competitive environment, Iran Home Appliances (P.J.S.) has established its Order-Production-Shipment infrastructure as flexible as possible to meet urgent customer demands and order modifications in line with customer expectations and satisfactions, and this flexibility principle is expected both from the company itself and suppliers as well as all other working partners.

The Company particularly expects the Suppliers, one of the most important rings of our supply chain, to provide similar flexibility to comply with this purpose. This expectation of Iran Home Appliances (P.J.S.) is described as not only delivery of orders in time, but also constantly cutting confirmed lead-times down and responding the changes in program as fast as possible.

All deliveries made by the supplier should conform to the amount and time stated in order letters; and the materials should be in full compliance with Iran Home Appliances (P.J.S.) Technical Drawings, Technical Specifications and Instructions as well as international Standards/Directives and Regulations.

The materials delivered to Iran Home Appliances (P.J.S.) must not contain prohibited substances, which are harmful to human health; and if allowed to be used restrictedly, the related substances must never exceed the limit.

Even though SvHC (Substances of Very High Concern) mentioned in REACH directive are not prohibited by EU yet, the supplier is obliged to notify Iran Home Appliances (P.J.S.) about when they use these substances in delivered materials.

Material Approval Process

After completing sample approval process held by Product Plants and meeting the conditions of pricing and payment inspected by Purchasing Directorate, the suppliers are given mass production orders by Production Planning Directorates under Iran Home Appliances (P.J.S.) production plants. Later, orders are confirmed and the materials are sent to the relevant product plants.

To ensure a sustainable growth in today’s highly competitive environment, Iran Home Appliances (P.J.S.) has established its Order-Production-Shipment infrastructure as flexible as possible to meet urgent customer demands and order modifications in line with customer expectations and satisfactions, and this flexibility principle is expected both from the company itself and suppliers as well as all other working partners.

The Company particularly expects the Suppliers, one of the most important rings of our supply chain, to provide similar flexibility to comply with this purpose. This expectation of Iran Home Appliances (P.J.S.) is described as not only delivery of orders in time, but also constantly cutting confirmed lead-times down and responding the changes in program as fast as possible.

All deliveries made by the supplier should conform to the amount and time stated in order letters; and the materials should be in full compliance with Iran Home Appliances (P.J.S.) Technical Drawings, Technical Specifications and Instructions as well as international Standards/Directives and Regulations.

The materials delivered to Iran Home Appliances (P.J.S.) must not contain prohibited substances, which are harmful to human health; and if allowed to be used restrictedly, the related substances must never exceed the limit.

Even though SvHC (Substances of Very High Concern) mentioned in REACH directive are not prohibited by EU yet, the supplier is obliged to notify Iran Home Appliances (P.J.S.) about when they use these substances in delivered materials.

Supplier Decommissioning

If one or several of the following conditions occur, decommissioning of supplier is triggered in line with Iran Home Appliances (P.J.S.)’s objectives and strategies.

- Supplier’s financial condition disruption

- Loss of financial advantage

- Quality-Logistics performance continuously below expectations

- Environment non-compliance

- Code of Conduct non-compliance

- Insufficient response to the requests of development/improvement by Iran Home Appliances (P.J.S.)

- Not to be able to cope with developing and changing industrial conditions

- Supplier’s violation of contract terms

The conditions above are decided upon via periodical reports of supplier performance, evaluation meetings basing upon these reports, strategies, end of contract period and new period pricing negotiations.

Supplier Performance Evaluation

Iran Home Appliances periodically assesses the performances of its suppliers within the framework of business results. Assessment criteria;

- Cost

- Quality

- Logistics

- Sustainability Index

- Cooperation

- Environment

The areas open to improvement are determined according to the results of performance evaluation and the supplier firm is asked to realize improvements. If the low performance continues, the supplier’s quota is reduced or the supplier is decommissioned.

Quality performance results of our current suppliers are shared with them every month on our supplier portal.

SUPPLIER REQUIREMENTS

Workplace Code Of Conduct

The Responsible Procurement Policy is designed to ensure that suppliers' business practices comply with Iran Home Appliances' values and current legal regulations, and compliance by all suppliers is mandatory. Accepting and complying with Iran Home Appliances' Responsible Procurement Policy is a contractual obligation. In the event of systematic and serious breaches of this Policy, Iran Home Appliances reserves the right to terminate the contract with its suppliers.

Our suppliers should develop this policy for their own suppliers and establish principles for its implementation. Compliance of sub-suppliers with the policy is evaluated in the Supplier Sustainability Index.

The policy is published on the Iran Home Appliances website and is also sent to suppliers as a circular.

Some details of our Responsible Purchasing Policy are given below.

Child labor: Suppliers shall not employ child labor in any way that violates applicable labor laws. Unless a higher age limit is specified in local laws, no one under the age of 15 who has not completed compulsory education shall be employed. Employees under the age of 18 shall not be employed in hazardous work or in night shifts to meet their educational needs.

Forced Labour; Human trafficking, forced and compulsory labour are never tolerated. No employer must require any employee to deposit a security deposit, provide a guarantee, or leave their identity in safekeeping before starting work. Employers must not force their employees to work through any form of threat, force, false claims, or other form of coercion. This requirement also includes forced labour through high-interest loan agreements, contracts, slavery/captivity, migrant labour, or other forms of labour.

Discrimination; Suppliers respect and accept ethnic and cultural differences, take measures to protect and promote diversity, and are committed to creating a work environment for their employees where equal opportunities exist, mutual trust prevails, discrimination is not free, and human rights are respected.

Freedom of Association and Collective Bargaining; Suppliers respect the right of their employees to unionize and their decision to join a union, as well as their rights to organize and bargain collectively in accordance with the law.

Harassment; any form of violation of the inviolability of supplier employees through physical, sexual, psychological and/or emotional harassment in the workplace or any location where they are present for work-related reasons will not be tolerated.

Compensation; Suppliers must ensure that the wages, overtime, and wage-related benefits paid to their employees comply with the applicable labor laws of the country in which they operate.

Working Hours; Suppliers must comply with the labor laws in force in the country in which they operate regarding working hours and leave entitlements. Unless local legislation specifies a lower maximum working hour limit and except in exceptional circumstances, suppliers must not require employees to work more than 48 hours regularly per week and more than 60 hours in total during a work week (including overtime). Suppliers must ensure that overtime is voluntary and paid in accordance with local and national laws or regulations. Except in exceptional circumstances, employees must have at least one day off in every seven-day period.

Application Principles

During audits of Iran Home Appliances' suppliers, their compliance with the rules in this Policy is questioned, corrective and preventive actions are initiated for non-conformities, improvements are expected, and follow-up audits are conducted to monitor these improvements.

Iran Home Appliances may request the dismissal of any supplier's employee or terminate the contract with any supplier that acts in violation of or inconsistent with applicable legal regulations.

Iran Home Appliances encourages and expects supplier employees to report non-compliance with this Policy. The following communication channels can be used to report suspicious behavior or violations of the rules in this Policy.

Web: www.zia.co.ir

Email: iha@zia.co.ir

Telephone: +982122214411

Iran Home Appliances is committed to handling all notifications confidentially and protecting the notification senders.

Iran Home Appliances will protect the confidentiality of anyone who reports suspicious behavior or a potential breach of business ethics by a supplier that violates this Policy, and will not tolerate any retaliation against that person.

Suppliers agree to accept any revisions to this Policy by Iran Home Appliances and to comply with the principles set forth herein by adopting Iran Home Appliances' Global Business Ethics Principles and related Policies.

Quality

Our suppliers should establish, document, implement and continually enhance the efficiency of a quality system which is aimed at performance improvement and reduction of the nonconformities and waste.

The suppliers should have quality objectives which could meet the expectations of Iran Home Appliances (P.J.S) including the requirements of material conformity, which are measurable and could be implemented in a certain timeframe in compliance with the quality policy.

The suppliers should have management reviews, which provide continual improvement. These reviews should cover the activity outputs aimed at monitoring the overall performance of the process.

All activities should be planned, implemented and controlled in a way minimizing the uncertainties in these activities and in the system as a whole and should realize the required improvements.

The items below are helpful in assessing whether the supplier meets the aforementioned expectations:

- Results of internal and external inspections

- Review records, performance results and objectives about the critical monitoring indicators of the processes affecting the product quality

- Customer quality awards

- Customer feedback records (product return rate, customer claims etc.)

- The certificates of standards obtained for the product (TSE, BEAB, VDE, DIN etc.)

- Having obtained certificates of management standards such as ISO 9001, ISO 14001, ISO/TS 16949, ISO 45001, ISO/IEC 17025

- Having a systematic structure for reporting and management of quality cost (The system should be able to generate periodic reports, direct the objectives, affect the management decisions and inspire the improvement projects.)

- Having a management representative who has the authority and responsibility to provide implementation and consistence of the quality system

Environment

Compliance with the Environmental Management System is required in all of our activities from the beginning of the commissioning process of our suppliers.

Our Responsible Purchasing Policy, which we have prepared for our suppliers, includes environmental conditions as well as the ethical principles and legal rules of our suppliers. The terms of compliance with the Responsible Purchasing Policy are specified in the contracts we have with all our suppliers.

In-house Supplier Sustainability Index has been prepared to closely monitor our suppliers' sustainability activities. This index monitors the performance of our suppliers' Economic, Environmental and Social activities throughout a comprehensive survey, which is the first step of the Supplier Sustainability Index Assessment.

As second part of the Supplier Sustainability Index Assessment, business audits, including but not limited to environmental issues, are carried out to check the compliance with environmental laws and regulations, support the environmental performance of our suppliers and to follow environmental activities closely.

In the qualitative part, the following questions are asked

- Sustainability reporting and tracking of environment/ energy performance KPIs

- Environmental Policy

- ISO 14001 Environmental Management Systems

- Compliance with environmental regulations and environmental penalties

- Compliance with Iran Home Appliances Chemicals Compliance Management Policy

- Operational eco efficiency- third party verification of the Scope 1-2 emissions with respect to the ISO 14064 Standard

The data we collect consists of:

- Direct and indirect Scope 1 and 2 emissions

- Water withdrawal in m3: surface, well water, public grid water, tanker water, and rainwater harvest

- Recycled wastewater, wastewater

- Hazardous and non-hazardous waste, and packaging waste

- Specific energy consumption (TOE/product)

- Green electricity purchased

- Renewable energy for self-consumption

The suppliers' environmental management system is questioned while the self-assessment is made during the application they make to the suppliers portal, and the ISO 14001 Environmental Management System certificate is requested. We undertake that we will not work with approximately 40 suppliers making 90% of our purchasing volume that do not have ISO 14001 certification by 2030.

We cooperate with suppliers from different sectors to minimize our environmental impact by reducing waste generation and increasing energy efficiency. We have been collecting environmental data including Scope 1–2 GHG emissions, waste, water, energy efficiency, and renewable energy from our direct material and OEM suppliers. We have plans to integrate logistics suppliers into the data collection process. As explained in detail, we intend to help our suppliers set environmental targets and track progress as part of our journey to becoming a Net-Zero company. There have been significant improvements in logistics emissions thanks to numerous actions in 2026.

7 tons of CO2 e greenhouse gas emissions were prevented by raising the through freight rates for the route from finished product storages to domestic storages. The pallets and cardboards left from the materials supplied by the facilities from abroad were used, thereby avoiding the cutting of 133 trees in return for 4 tons of paper and 17 tons of pallets. Iran Home Appliances increased the seaway usage rate for international shipping operations to 30% in 2025 and set the target for 2026 as 60%. As part of this, the company attaches priority to railway transport as well. It aims to boost the railway usage rate in 2026. For transportation from storages to Iranian ports, the use of railways began as an alternative to the use of highways. Thus, cost advantage was obtained in domestic shipments and an environmental contribution was made with low-emission transport.

Our main expectation is that our suppliers comply with the list of Iran Home Appliances banned / restricted substances in order to present environmentally friendly products to the customer. The Iran Home Appliances Chemical Compatibility Specification requirements an important part of our environmental expectations that we expect from our suppliers.

Compliance Specification requirements below, also constitute a significant element of our environmental expectations from the suppliers.

Iran Home Appliances Chemical Compliance Specification

SUPPLIER RELATIONSHIP

Supplier Relationship

Supplier Sustainability Training Program

An important part of our approach consists of working with suppliers to ensure continuous improvement.

In 2021, Iran Home Appliances started to provide consultancy services to its suppliers on sustainability issues through a third-party independent institution reaching 800 person*hours. In addition, we began a program that provides sustainability training to our suppliers through non-governmental organizations and direct webinars. The program includes a wide range of topics such as supplier sustainability practices and strategies, energy efficiency and renewable energy applications, greenhouse gas inventory calculation method, conflict minerals, energy and environmental data collection, and risk Identification. To increase our reach and participation rate, we initiated the Digital Education Platform project in 2025 with the aim of digitizing our training programs. By 2027, our suppliers will be able to easily access the training through this platform.

Supplier Improvement Activities

Iran Home Appliances’ Auxiliary Industry Transformation and Development Department aims to increase production quality and efficiency of suppliers, support them towards adopting a sustainable production approach, and help them to maintain their competitiveness. We analyze the needs of suppliers and ensure access to resources allocated for further cooperation. To increase process efficiency by creating integration between Iran Home Appliances and auxiliary industries, the New Supplier Management System Project is carried out at the suppliers and Iran Home Appliances businesses selected as pilots. The project, which aims to digitize supplier management, especially order, stock, and logistics, is planned to be expanded in 2026.

In 2025, we directed our focus on developing supplier infrastructure and technical competencies and continuously expanding emerging production technologies in the supplier ecosystem.

With the Iran Home Appliances Supplier Technology Day, which has 40 participating suppliers, we aim to support digital transformation and process technologies by training suppliers in quality and efficiency optimization in thermoform processes with the digital twin methods, quality-enhancing digital solutions in surface control applications, new applications to reduce scrap and waste in the sheet metal forming process, and in the use of nanotechnology in the coating process and its reflections on the household durables sector. In addition, we carried out a total of 12 projects with 16 suppliers: 7 in quality improvement, 3 in digital transformation, and 2on productivity increase. In 2025, within the scope of efficiency studies, process optimization, cycle times improvement, automation solutions, localization, optimization of quality control activities and digital transformation projects, Euro 20 thousand was saved.